Tsumi

[H]F Junkie

- Joined

- Mar 18, 2010

- Messages

- 13,760

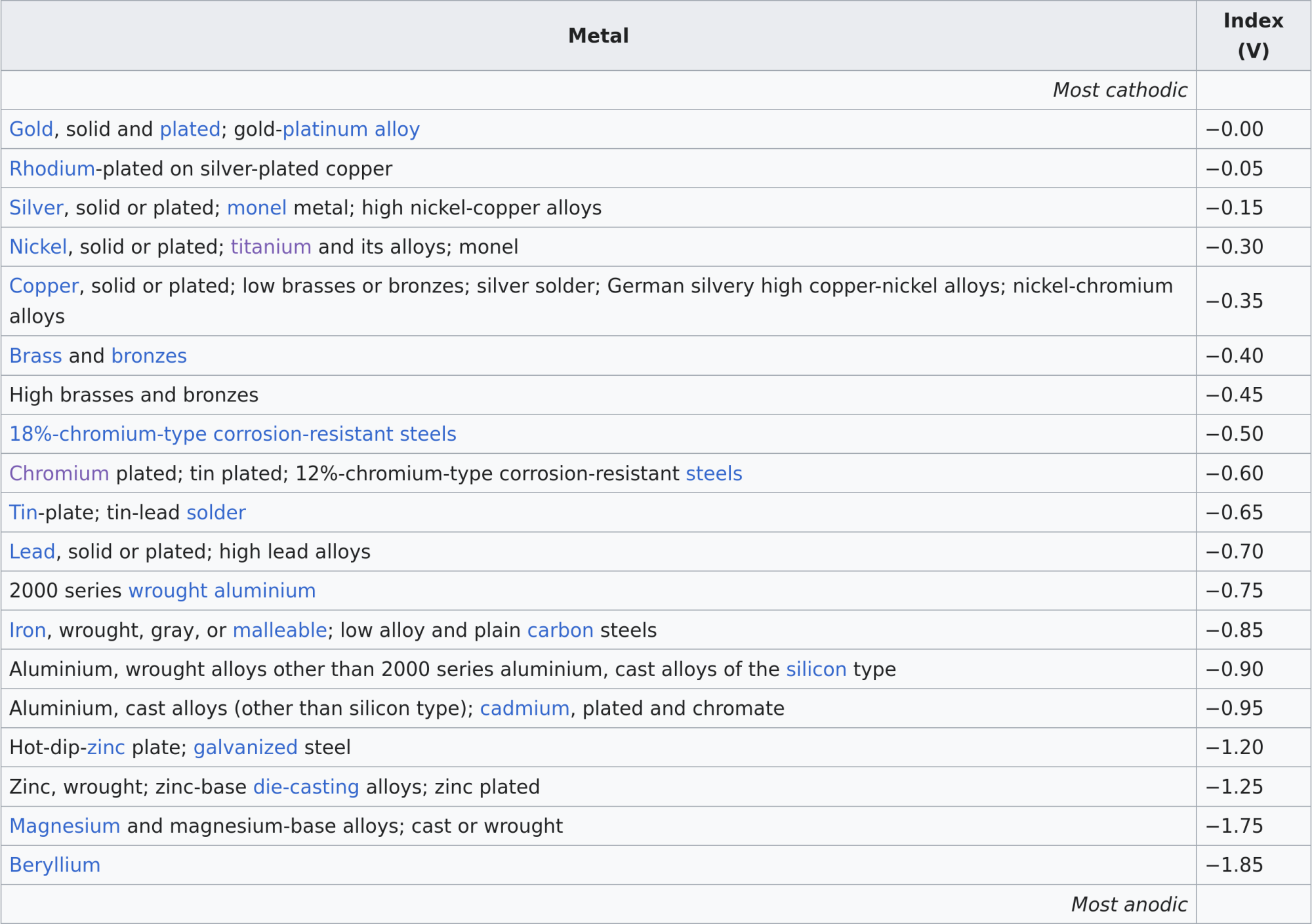

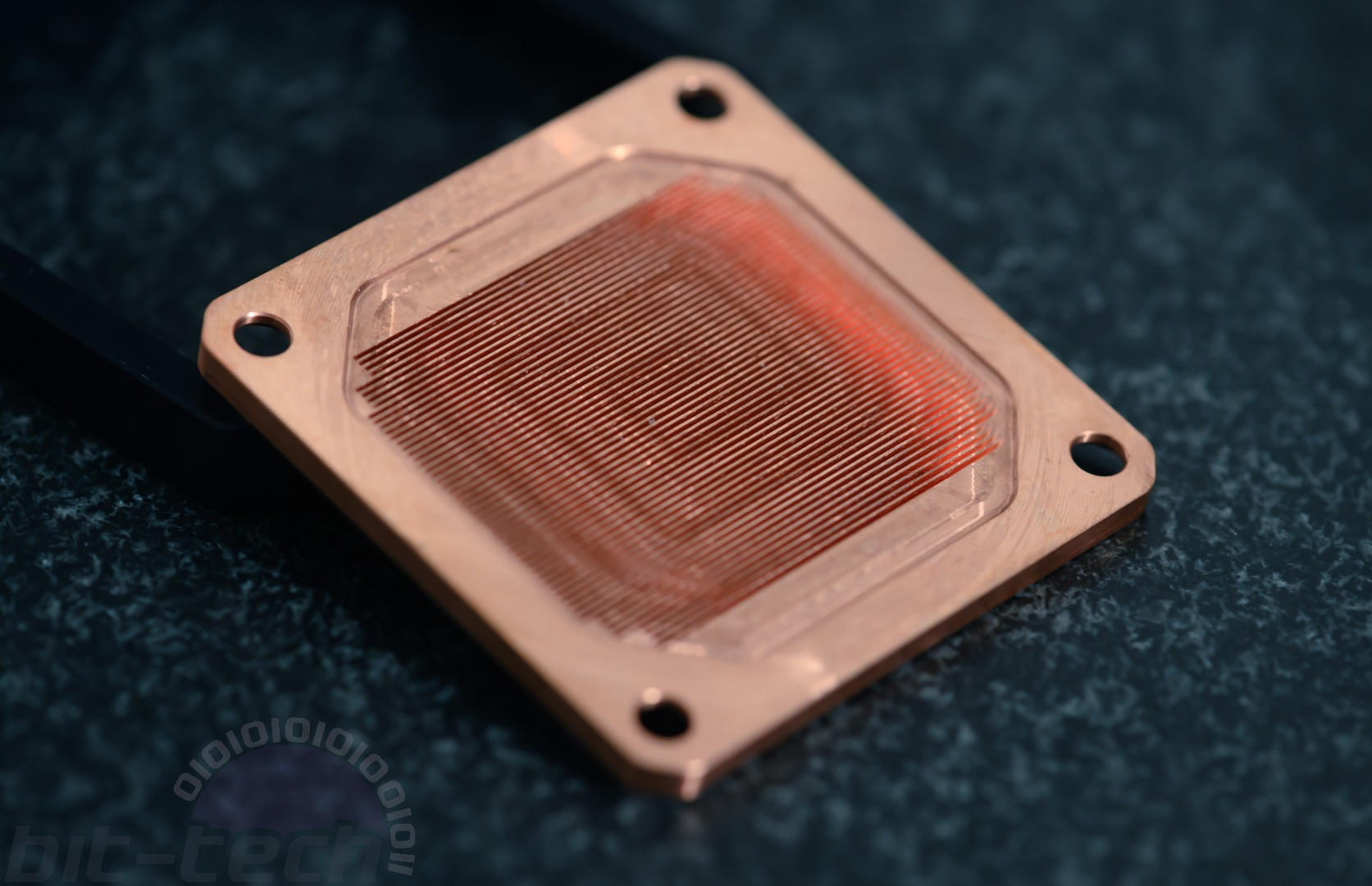

Apparently Igor's lab did a material analysis of a few radiators and found that many of them advertised as full copper actually had brass channels. The most glaring violation IMO were Bykski using leaded solder in addition to brass channels.

https://www.igorslab.de/en/the-big-...ition-water-cooling-on-the-test-bench-part-1/

Would be interesting what his future cutting up of radiators reveal.

https://www.igorslab.de/en/the-big-...ition-water-cooling-on-the-test-bench-part-1/

Would be interesting what his future cutting up of radiators reveal.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)