Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Temp Check

- Thread starter Light1984

- Start date

pendragon1

Extremely [H]

- Joined

- Oct 7, 2000

- Messages

- 52,266

improve what?!

I've been out of the game for awhile, so I'm not sure what's what. I read 40C on coolant is a little high, so I'm not sure if 36 is pushing up too close to that. I do have acrylic tubing, so I think it can handle more, but just checking to see what anyone with more experience might think.

Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,879

Hello again,

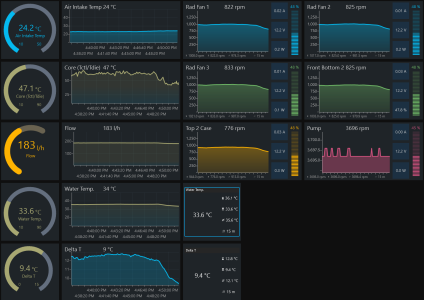

I just finished installing water cooling kit on my PC and was wondering if these temps look acceptable and if there is anything I can do to improve them if not. Delta T maxed at 12.8C, water temp maxed at 36.1C. This is an hour or so of gaming.

View attachment 602471

There is a lot of data to absorb there, but if I interpret the labels of your temperature sensors correctly, this looks pretty reasonable, if this is a fully heat soaked system after a period of full load.

CPU's tend to benefit much less temperature wise than GPU's do, presumably because of the heat spreader getting in the way.

Provided this captures a period of high load, I see nothing in this chart that stands out as negative.

You might see a couple of degree improvement in core temps by actually running the pump at full speed, but that's about it.

There is a lot of data to absorb there, but if I interpret the labels of your temperature sensors correctly, this looks pretty reasonable, if this is a fully heat soaked system after a period of full load.

CPU's tend to benefit much less temperature wise than GPU's do, presumably because of the heat spreader getting in the way.

Provided this captures a period of high load, I see nothing in this chart that stands out as negative.

You might see a couple of degree improvement in core temps by actually running the pump at full speed, but that's about it.

Thanks for the info. I will do some longer testing to make sure. If I run the pump over 50%, the flow meter makes an awful ticking sound. I've reached out to Aquacomputer and am waiting to hear back about a replacement. I will try higher pump speeds once I get a replacement.

Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,879

Thanks for the info. I will do some longer testing to make sure. If I run the pump over 50%, the flow meter makes an awful ticking sound. I've reached out to Aquacomputer and am waiting to hear back about a replacement. I will try higher pump speeds once I get a replacement.

I have a couple of aquacomputer flow meters in my systemm and have experienced this ticking sound in the past.

It is my experience that it goes away over time, but it can take a while, up to a few weeks of heavy use.

I think what happens is that air gets caught in there, and it needs time to work its way out of the system.

What usually do is monitor temps in two places, once before the blocks, and once after them.

The temperature going into the blocks controls the radiator fan speeds, as if the incoming water is too warm, then the only thing that can solve it is more fans. The temperature coming out of the blocks controls the pump speed, as if it is too hot leaving the blocks, the fastest way to get it cooler is to pump fresh cooler water into the blocks faster.

In my system I set the incoming pre-block target temp 1.5C below the outflowing post block temp, as this results in the best balance, but my system is crazy power/heat hungry with a 24C/48T threadripper that loves running hot and a 4090 that does the same. With other hardware, you may find that the difference in temp between the two is lower. It all depends on how much heat your blocks are dumping into the system.

If you configure your loop this way you want the temp sensors as close as possible so there is less lag in response when temp changes. So th epre-block sensor is right at the first block inlet, and the post block sensor is right after the second blocks outlet.

This - of course - assumes that both your blocks are in a row like mine are, but you could do something similar with four temperature sensors and averaging the inlet temps with eachother and the outlet temps with eachother. (or maybe even taking the max of both for more responsiveness.

Either eway, the result in my loop was that the fan ticking would only happen when the system was at high load and requesting more speed out of the pump, and when it did the fans usually drowned out the ticking anyway, so it wasn't as bad.

Over time, the shifting pump speeds helped work the air bubbles out, and after a few weeks, the ticking more or less disappeared.

freeagentt

Gawd

- Joined

- Dec 5, 2018

- Messages

- 551

Looks warm to me. It is about 20c warmer than mine with an air cooler. At least for the idle.

Furthermore, I just realized I've been looking at Tctl/Tdie for reported temp on CPU and I should be looking at Tdie on Ryzen. So... my CPU idles way lower than I thought. I think im happy with this. Thank you everyone for your feedback and help.If the hardware in your sig is current and that is running full tilt with a warmed up loop looks like you are spot on with what you have going on.

Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 38,879

Oh, and one final recommendation.

Since you have an aquaero device, maximize your target temp / fan and pump speeds by using setpoint controllers instead of curve controllers.

Curve controllers only work accurately at the max target temp, at every other load they spin the fans faster than necessary, and thus keep the temps below where your intended target is.

With a setpoint controller (aka PID controller) at least than max loads your fans (and pumps should you choose to control their speeds) will target the same target temp at any heat load, and thus at sub max heat loads will have much quieter fan speeds.

Custom PID control is very complicated. People (mostly German manyfacturing engineers) have done Masters and PhD dissertation on getting the PID settings right. The aquaero allows for this under "custom" settings, but I would t recommend it.

Fortunately they have some presets that work pretty well for PC water-cooling setups, so you just choose the desired response speed (slowest, slower, normal, faster, fastest) instead of doing complicated experiments on your loop.

Slower settings lead to more stable fan speeds, at the cost of less accuracy in hitting the temp setting. Faster speeds get to to the temp setting faster, but can lead to rapidly changing fan speeds which can be disruptive, as well as oscillation. (It's hot turn up the fans, shit it's too cold turn off the fans, over and over. I call Thai the girlfriend thermostat effect.)

In my loop "Normal" is the fastest I can use without inducing oscillation.

You may need to set minimum fan/pump speeds for this to work right though, as many fans and pumps turn off below a certain duty cycle percentage, which in and of itself can cause oscillation.

I'd recommend configuring the minimum fan/pump speeds as the slowest duty cycle setting they will actually run at without shutting off.

Since you have an aquaero device, maximize your target temp / fan and pump speeds by using setpoint controllers instead of curve controllers.

Curve controllers only work accurately at the max target temp, at every other load they spin the fans faster than necessary, and thus keep the temps below where your intended target is.

With a setpoint controller (aka PID controller) at least than max loads your fans (and pumps should you choose to control their speeds) will target the same target temp at any heat load, and thus at sub max heat loads will have much quieter fan speeds.

Custom PID control is very complicated. People (mostly German manyfacturing engineers) have done Masters and PhD dissertation on getting the PID settings right. The aquaero allows for this under "custom" settings, but I would t recommend it.

Fortunately they have some presets that work pretty well for PC water-cooling setups, so you just choose the desired response speed (slowest, slower, normal, faster, fastest) instead of doing complicated experiments on your loop.

Slower settings lead to more stable fan speeds, at the cost of less accuracy in hitting the temp setting. Faster speeds get to to the temp setting faster, but can lead to rapidly changing fan speeds which can be disruptive, as well as oscillation. (It's hot turn up the fans, shit it's too cold turn off the fans, over and over. I call Thai the girlfriend thermostat effect.)

In my loop "Normal" is the fastest I can use without inducing oscillation.

You may need to set minimum fan/pump speeds for this to work right though, as many fans and pumps turn off below a certain duty cycle percentage, which in and of itself can cause oscillation.

I'd recommend configuring the minimum fan/pump speeds as the slowest duty cycle setting they will actually run at without shutting off.

Last edited:

Oh, and one final recommendation.

Since you have an aquarium device, maximize your target temp / fan and pump speeds by using setpoint controllers instead of curve controllers.

Curve controllers only work accurately at the max target temp, at every other load they spin the fans faster than necessary, and thus keep the temps below where your intended target is.

With a setpoint controller (aka PID controller) at least than max loads your fans (and pumps should you choose to control their speeds) will target the same target temp at any heat load, and thus at sub max heat loads will have much quieter fan speeds.

Custom PID control is very complicated. People (mostly German manyfacturing engineers) have done Masters and PhD dissertation on getting the PID settings right. The aquaero allows for this under "custom" settings, but I would t recommend it.

Fortunately they have some presets that work pretty well for PC water-cooling setups, so you just choose the desired response speed (slowest, slower, normal, faster, fastest) instead of doing complicated experiments on your loop.

Slower settings lead to more stable fan speeds, at the cost of less accuracy in hitting the temp setting. Faster speeds get to to the temp setting faster, but can lead to rapidly changing fan speeds which can be disruptive, as well as oscillation. (It's hot turn up the fans, shit it's too cold turn off the fans, over and over. I call Thai the girlfriend thermostat effect.)

In my loop "Normal" is the fastest I can use without inducing oscillation.

You may need to set minimum fan/pump speeds for this to work right though, as many fans and pumps turn off below a certain duty cycle percentage, which in and of itself can cause oscillation.

I'd recommend configuring the minimum fan/pump speeds as the slowest duty cycle setting they will actually run at without shutting off.

Thank you for this. I'm a mechanical engineer by trade so I have quite I but of experience with PID feedback loops. I'll check it out and see how she does. Really appreciate all the detailed info you've provided.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)