Zarathustra[H]

Extremely [H]

- Joined

- Oct 29, 2000

- Messages

- 39,111

Or so says Igor:

https://www.igorslab.de/en/rest-in-peace-12vhpwr-connector-welcome-12v-2x6-connector/

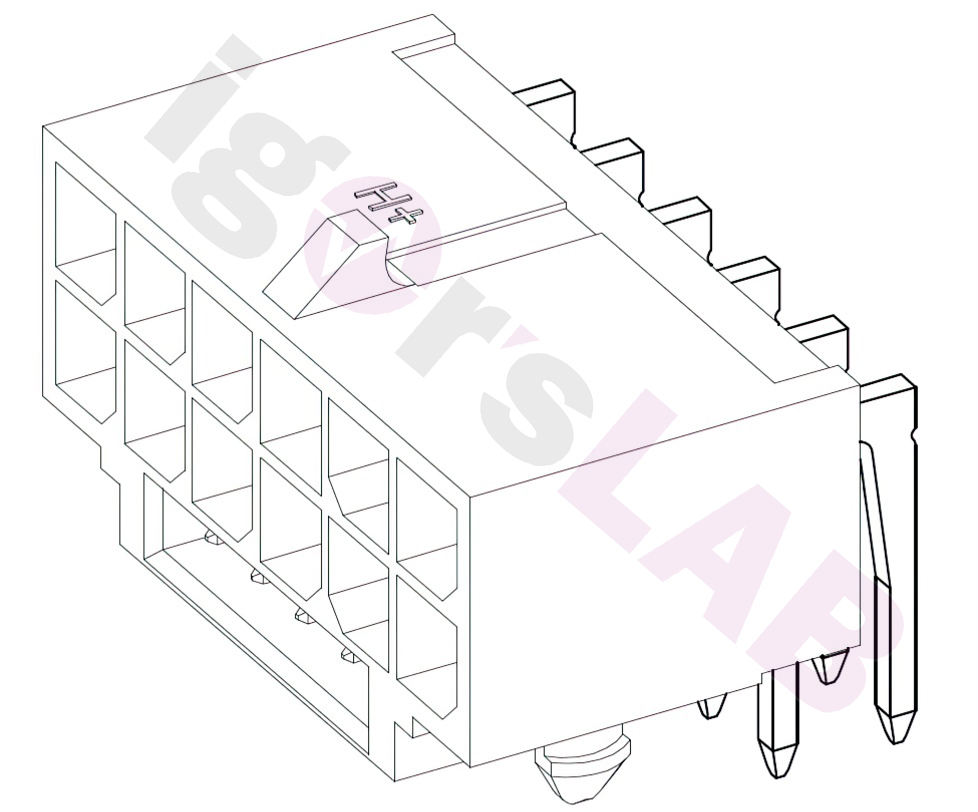

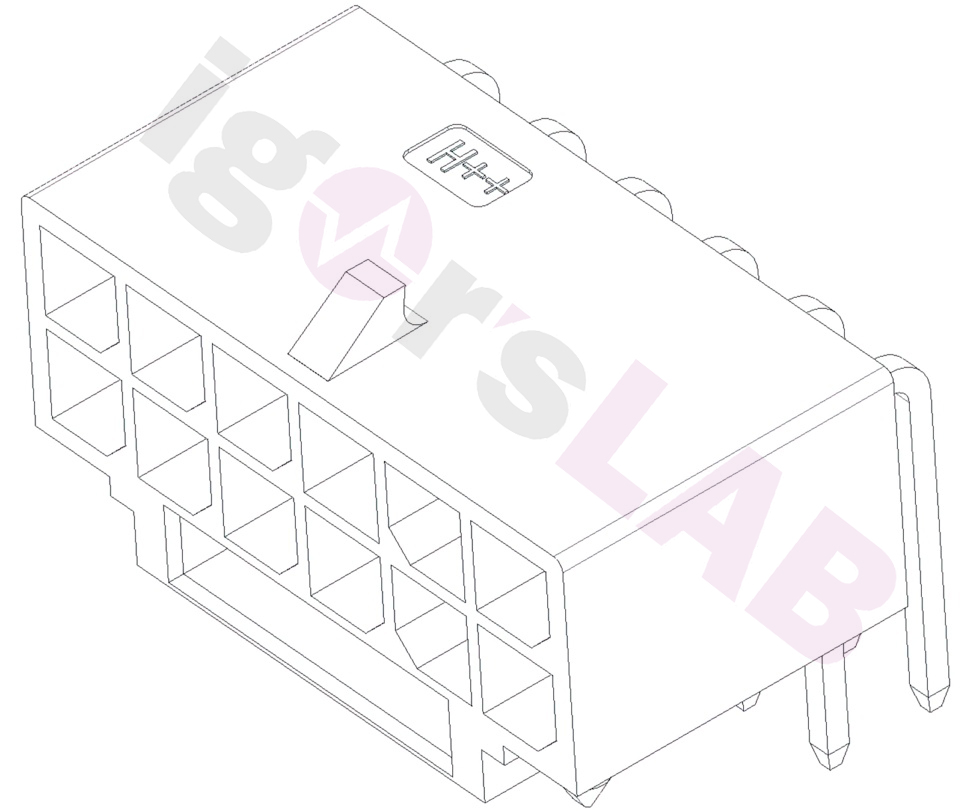

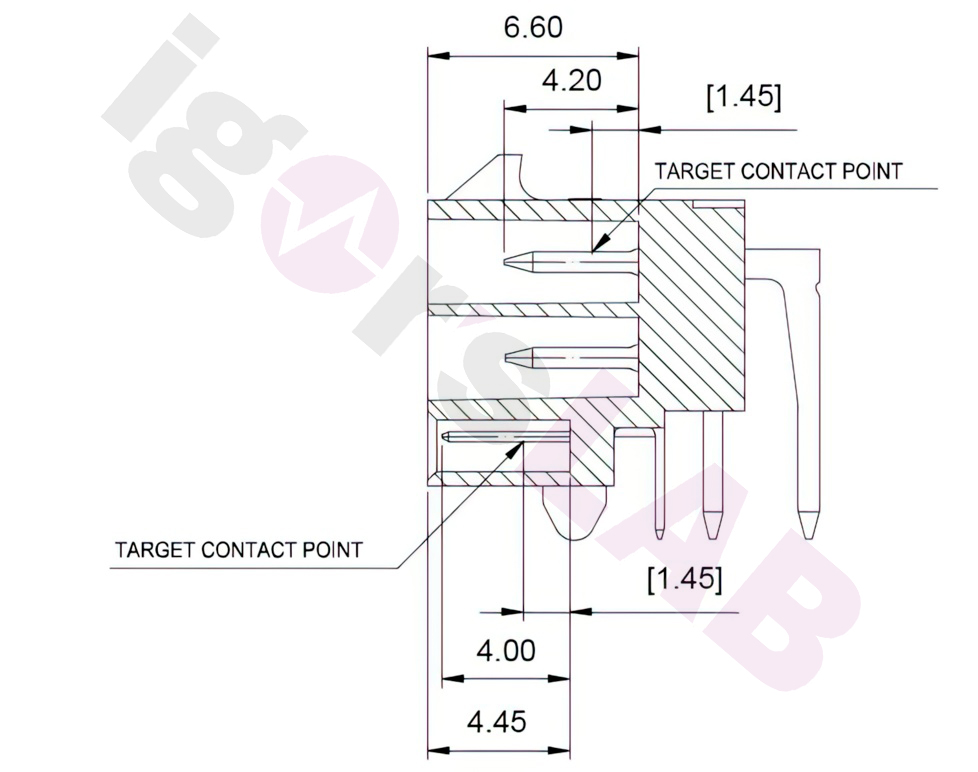

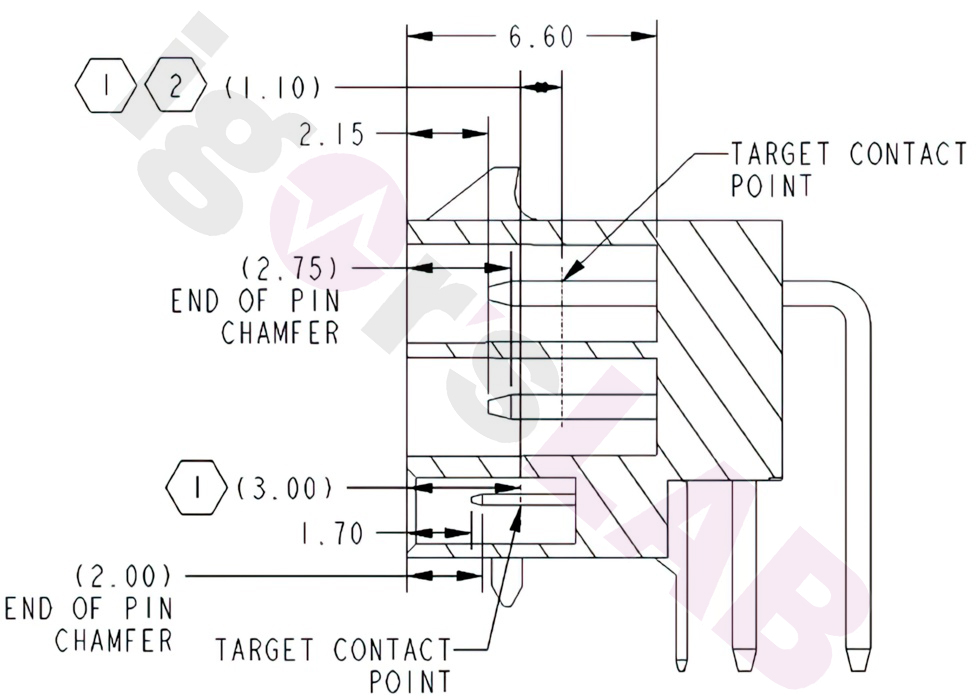

According to Igor it is slated to be replaced with a new connector (which looks very much like the old connector) called 12V-2×6, and supporting up to 675w.

As far as I am concerned, I am glad to see 12VHPWR go the way of the dodo, but IMHO this thing should never have launched in the first place. it was a design blunder.

All of that said, to me it looks more like a design revision than a new connector, but I am at least happy they are doing something.

https://www.igorslab.de/en/rest-in-peace-12vhpwr-connector-welcome-12v-2x6-connector/

According to Igor it is slated to be replaced with a new connector (which looks very much like the old connector) called 12V-2×6, and supporting up to 675w.

As far as I am concerned, I am glad to see 12VHPWR go the way of the dodo, but IMHO this thing should never have launched in the first place. it was a design blunder.

All of that said, to me it looks more like a design revision than a new connector, but I am at least happy they are doing something.

Last edited:

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)