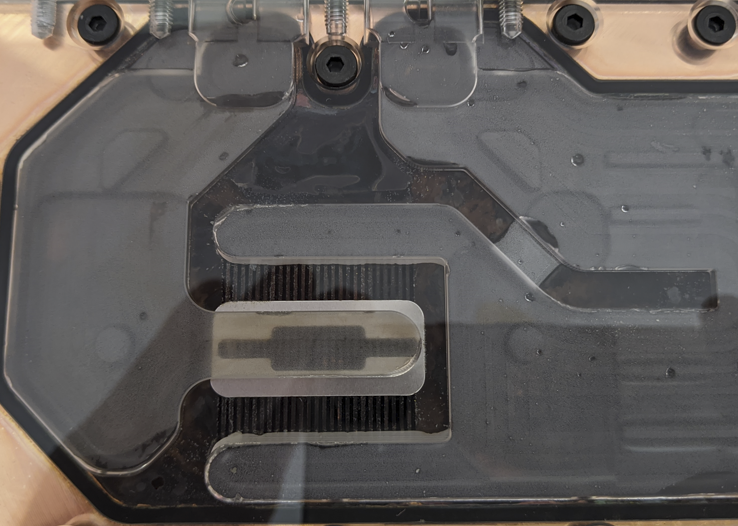

I have always used distilled water and copper blocks with PT Nuke and a Silver Kill Coil Strip.

I could not get a plane copper block for the RTX4090. What is the best additive for a distilled water, copper CPU and RADs with a Chrome-plated copper?

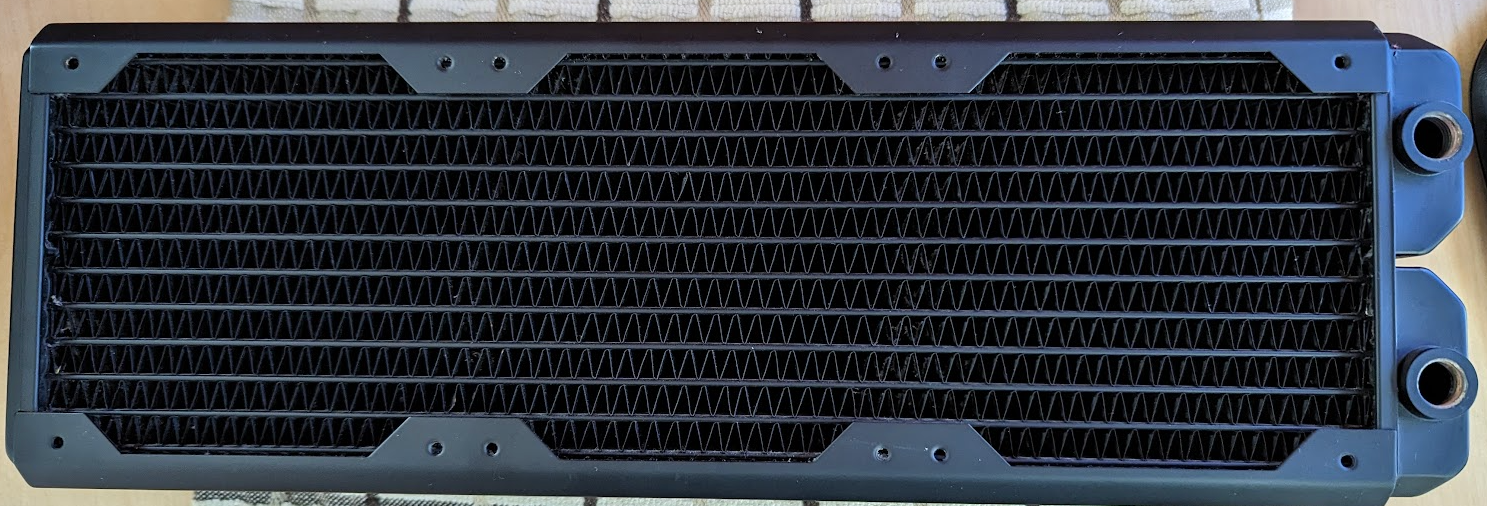

I assume the RADs are copper as one has a small leak on two sides that I can see.

Can anyone tell what brand they are? I can't see the logo and it was too long ago.

I was not wanting to redo the loop but it seems the radiators need to be replaced.

I was kind of wanting to replace the 12 DC fans with pwm fans but they work.

I could not get a plane copper block for the RTX4090. What is the best additive for a distilled water, copper CPU and RADs with a Chrome-plated copper?

I assume the RADs are copper as one has a small leak on two sides that I can see.

Can anyone tell what brand they are? I can't see the logo and it was too long ago.

I was not wanting to redo the loop but it seems the radiators need to be replaced.

I was kind of wanting to replace the 12 DC fans with pwm fans but they work.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)