Hello everyone!

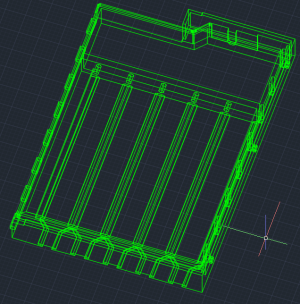

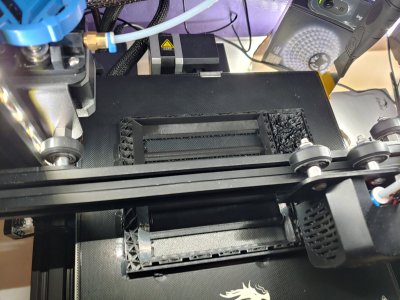

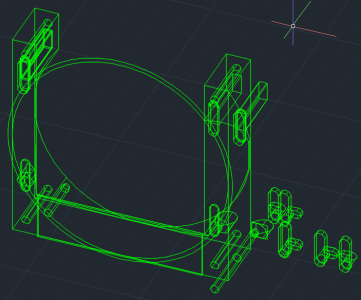

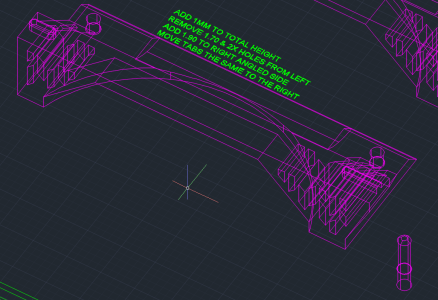

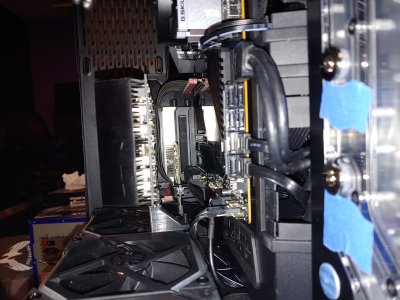

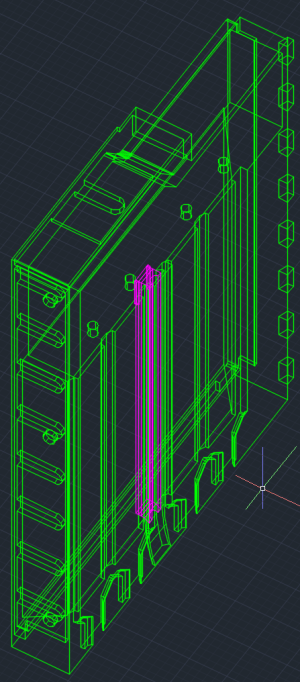

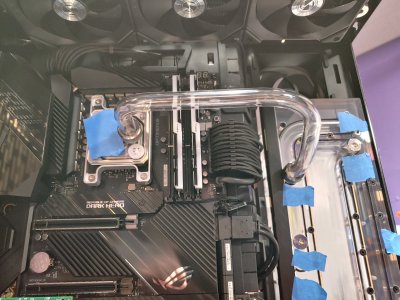

I am finally getting around to posting my worklog. It's been functional since July, but there is another significant mod I want to make. I learned a lot making this build, unique to me was having access to the full case 3d model from Lian Li, as well as a new 3d printer.

Thematically I wanted to try and make rgb look good, and not do a standard all black / red type case as I have done in the past. After deciding upon the Lian Li O11 Dynamic XL, I wanted to focus thematically on the contrast of transparency and darkness. This is where the name came from.

Enough intro, let's start things off with a parts list & photo of the good stuff!

Case: Lian Li O11 Dynamic XL (check this link if you're unfamiliar https://lian-li.com/product/pc-o11d-rog/)

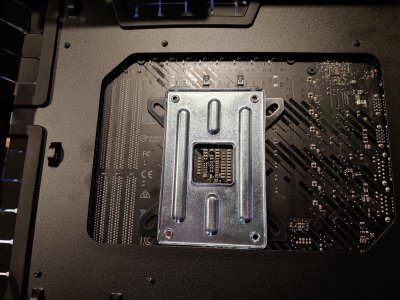

Motherboard: Asus X570 Crosshair VIII Dark Hero

CPU: AMD Ryzen 5950x

RAM: G.SKILL Trident Z Neo 2x16GB F4-3800C14D-32GTZN 3,800 Mhz / 14-16-16-36

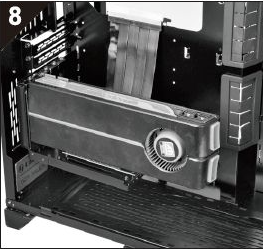

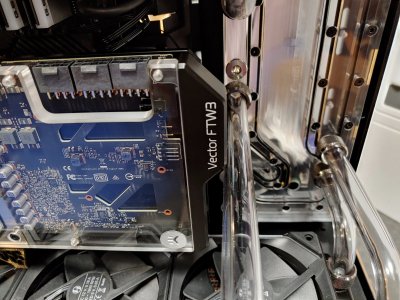

GPU: EVGA GeForce RTX 3090 FTW3 ULTRA GAMING 24G-P5-3987-KR

PSU: Seasonic FOCUS PX-850 80+ Platinum

PSU Extensions: LINKUP 30cm Braided w/Comb Kit ┃1 x 24 P (20+4)┃2 x 8 P (4+4) CPU┃3 x 8 P (6+2) GPU Set┃300mm Black

SSD (Primary): WD Black SN850 PCIe NVMe 4.0 2TB

SSD (Secondary): Inland Premium PCIe NVMe 3.0 1TB

Fiber NIC: Mellanox MCX311A-XCAT CX311A ConnectX-3 10GbE SFP+

PCIe risers: LINKUP PCIe 4.0 X16 90 Degree Socket 15cm, LINKUP PCIE 3.0 16x Straight Socket 10 cm

USB hub: Sabrent 5 Port Internal USB 3.0 Hub Controller HB-INTR

Cooling components:

Radiator fans: Lian Li Uni Fan SL120 Black x6

Case fan: Arctic P12 PWM PST

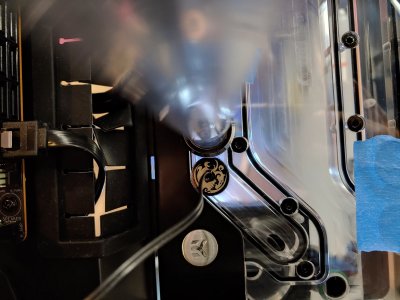

Reservoir: Lian Li O11D Distribution Plate G1 by EK

Pump: Swiftech MCP35X 12V DC Pump with EK-DDC Heatsink Housing Black

Radiators: Hardware Labs Black Ice Nemesis 360GTS x2

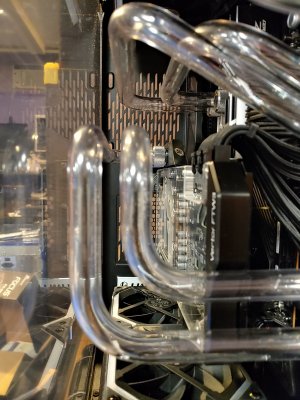

CPU Block: EK-Quantum Magnitude D-RGB AM4 Nickel + Plexi

GPU Block: EK-Quantum Vector FTW3 RTX 3080/3090 D-RGB Nickel + Plexi with EK-Quantum Vector FTW3 RTX 3080/3090 Backplate Black

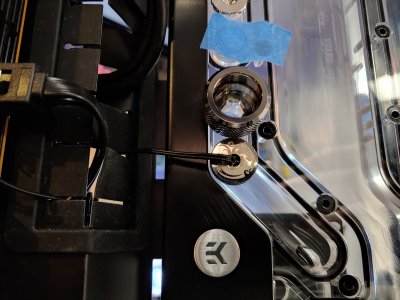

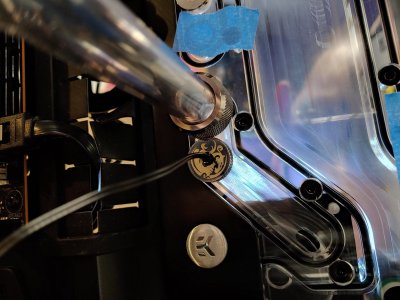

Fittings: Bitspower G1/4" Black Sparkle Advanced Multi-Link For OD 16MM x16, Bitspower G 1/4" Temperature Sensor Plug Black Sparkle, Bitspower G 1/4" Mini Valve Matte Black

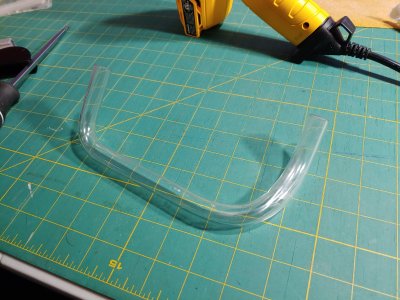

Tubing: EK-HD PETG Tube 12/16mm

Coolant: EK-CryoFuel Clear

I am finally getting around to posting my worklog. It's been functional since July, but there is another significant mod I want to make. I learned a lot making this build, unique to me was having access to the full case 3d model from Lian Li, as well as a new 3d printer.

Thematically I wanted to try and make rgb look good, and not do a standard all black / red type case as I have done in the past. After deciding upon the Lian Li O11 Dynamic XL, I wanted to focus thematically on the contrast of transparency and darkness. This is where the name came from.

Enough intro, let's start things off with a parts list & photo of the good stuff!

Case: Lian Li O11 Dynamic XL (check this link if you're unfamiliar https://lian-li.com/product/pc-o11d-rog/)

Motherboard: Asus X570 Crosshair VIII Dark Hero

CPU: AMD Ryzen 5950x

RAM: G.SKILL Trident Z Neo 2x16GB F4-3800C14D-32GTZN 3,800 Mhz / 14-16-16-36

GPU: EVGA GeForce RTX 3090 FTW3 ULTRA GAMING 24G-P5-3987-KR

PSU: Seasonic FOCUS PX-850 80+ Platinum

PSU Extensions: LINKUP 30cm Braided w/Comb Kit ┃1 x 24 P (20+4)┃2 x 8 P (4+4) CPU┃3 x 8 P (6+2) GPU Set┃300mm Black

SSD (Primary): WD Black SN850 PCIe NVMe 4.0 2TB

SSD (Secondary): Inland Premium PCIe NVMe 3.0 1TB

Fiber NIC: Mellanox MCX311A-XCAT CX311A ConnectX-3 10GbE SFP+

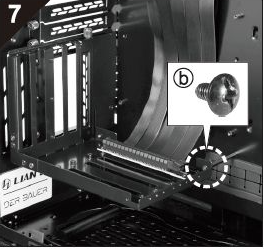

PCIe risers: LINKUP PCIe 4.0 X16 90 Degree Socket 15cm, LINKUP PCIE 3.0 16x Straight Socket 10 cm

USB hub: Sabrent 5 Port Internal USB 3.0 Hub Controller HB-INTR

Cooling components:

Radiator fans: Lian Li Uni Fan SL120 Black x6

Case fan: Arctic P12 PWM PST

Reservoir: Lian Li O11D Distribution Plate G1 by EK

Pump: Swiftech MCP35X 12V DC Pump with EK-DDC Heatsink Housing Black

Radiators: Hardware Labs Black Ice Nemesis 360GTS x2

CPU Block: EK-Quantum Magnitude D-RGB AM4 Nickel + Plexi

GPU Block: EK-Quantum Vector FTW3 RTX 3080/3090 D-RGB Nickel + Plexi with EK-Quantum Vector FTW3 RTX 3080/3090 Backplate Black

Fittings: Bitspower G1/4" Black Sparkle Advanced Multi-Link For OD 16MM x16, Bitspower G 1/4" Temperature Sensor Plug Black Sparkle, Bitspower G 1/4" Mini Valve Matte Black

Tubing: EK-HD PETG Tube 12/16mm

Coolant: EK-CryoFuel Clear

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)