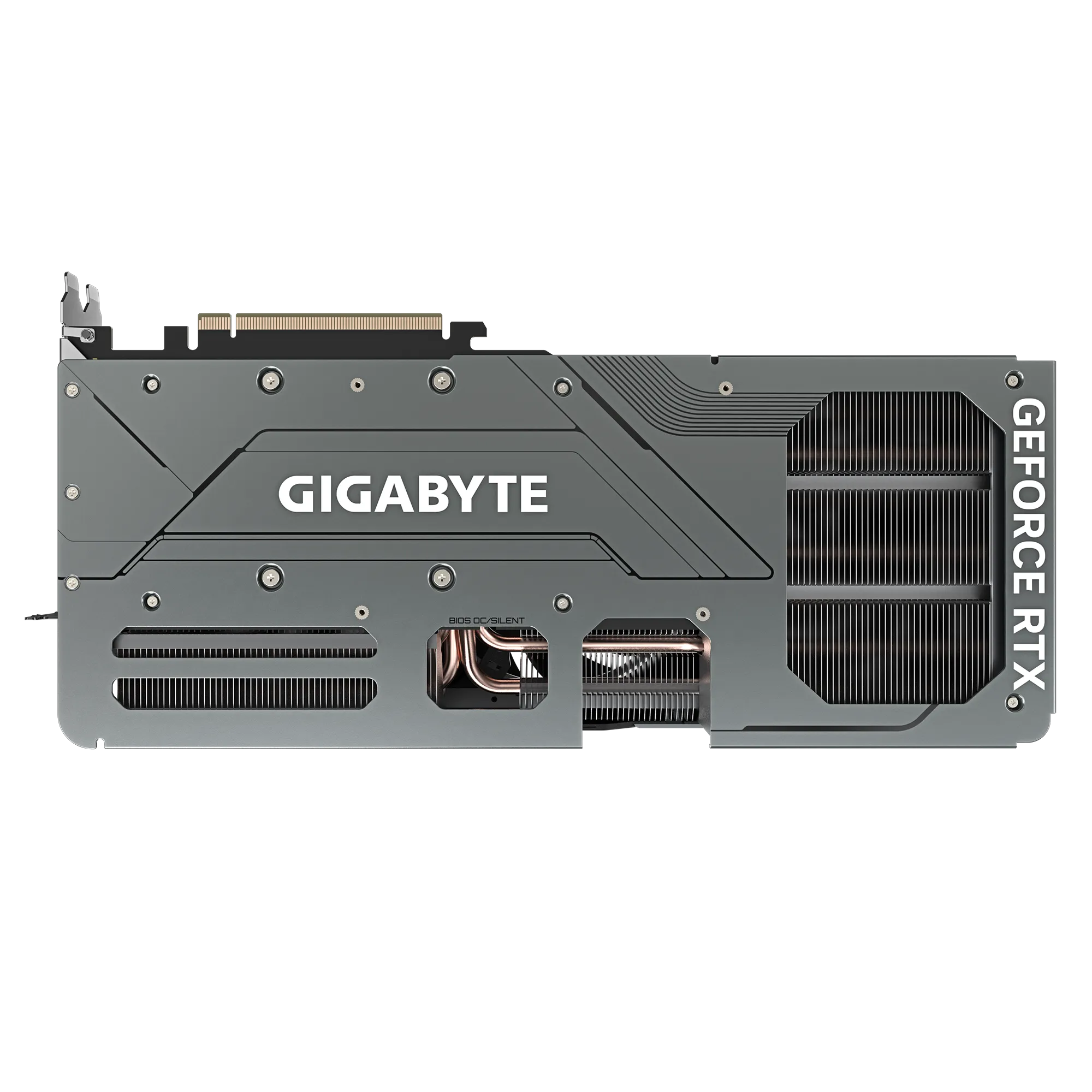

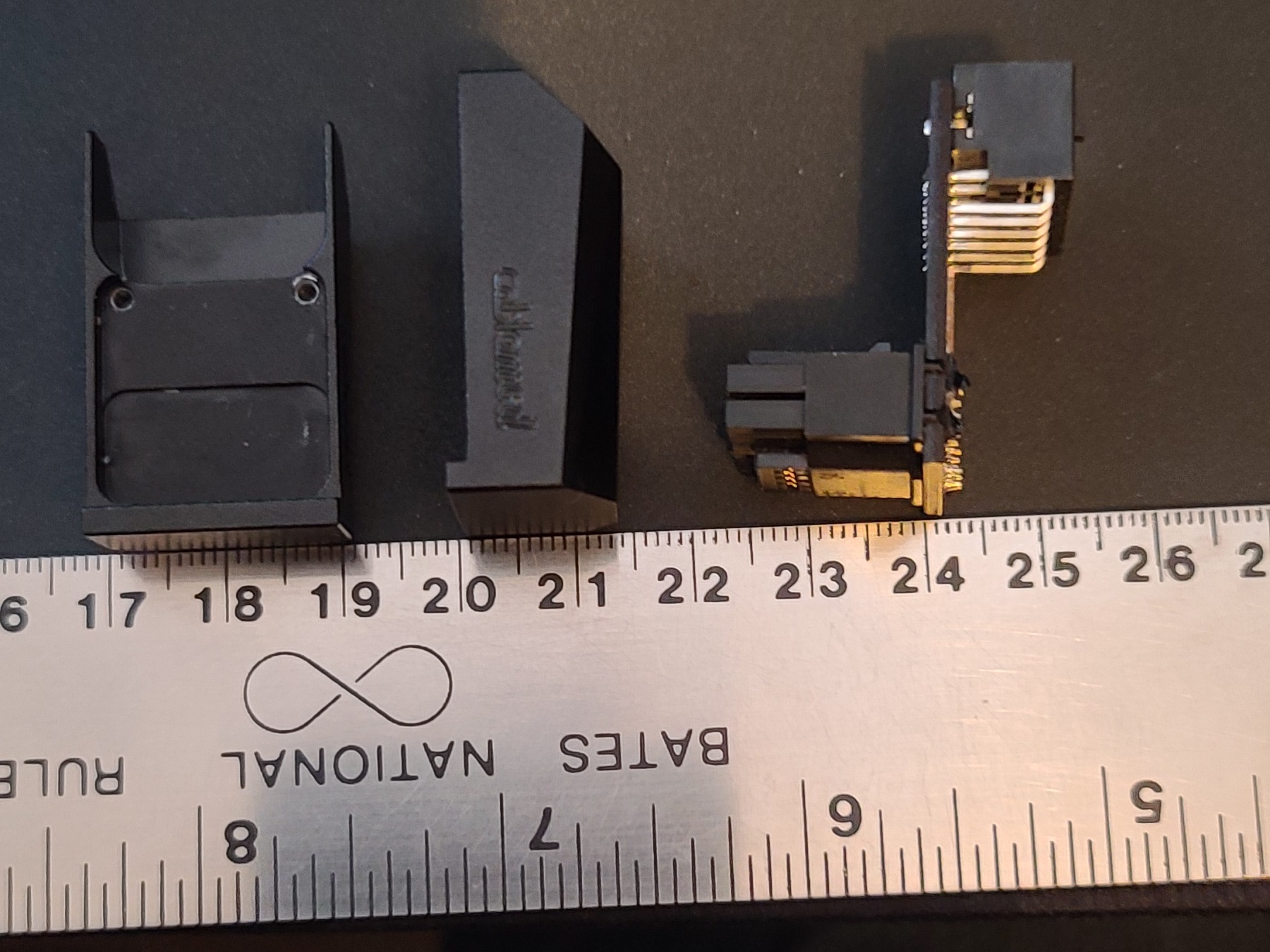

Any 12VHPWR connector can overheat with a high enough power draw and improper seating. By now most new cards that use the 12x6+4 connector should be shipping with the 12V-2x6 connector rather than the 12VHPWR, especially nVidia ones. It is possible some AIBs would try to use up their existing stock of 12VHPWR connectors before switching to the 12V-2x6 connector.

Nvidia doesn't ship AIB's the cards with the connector already attached?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)