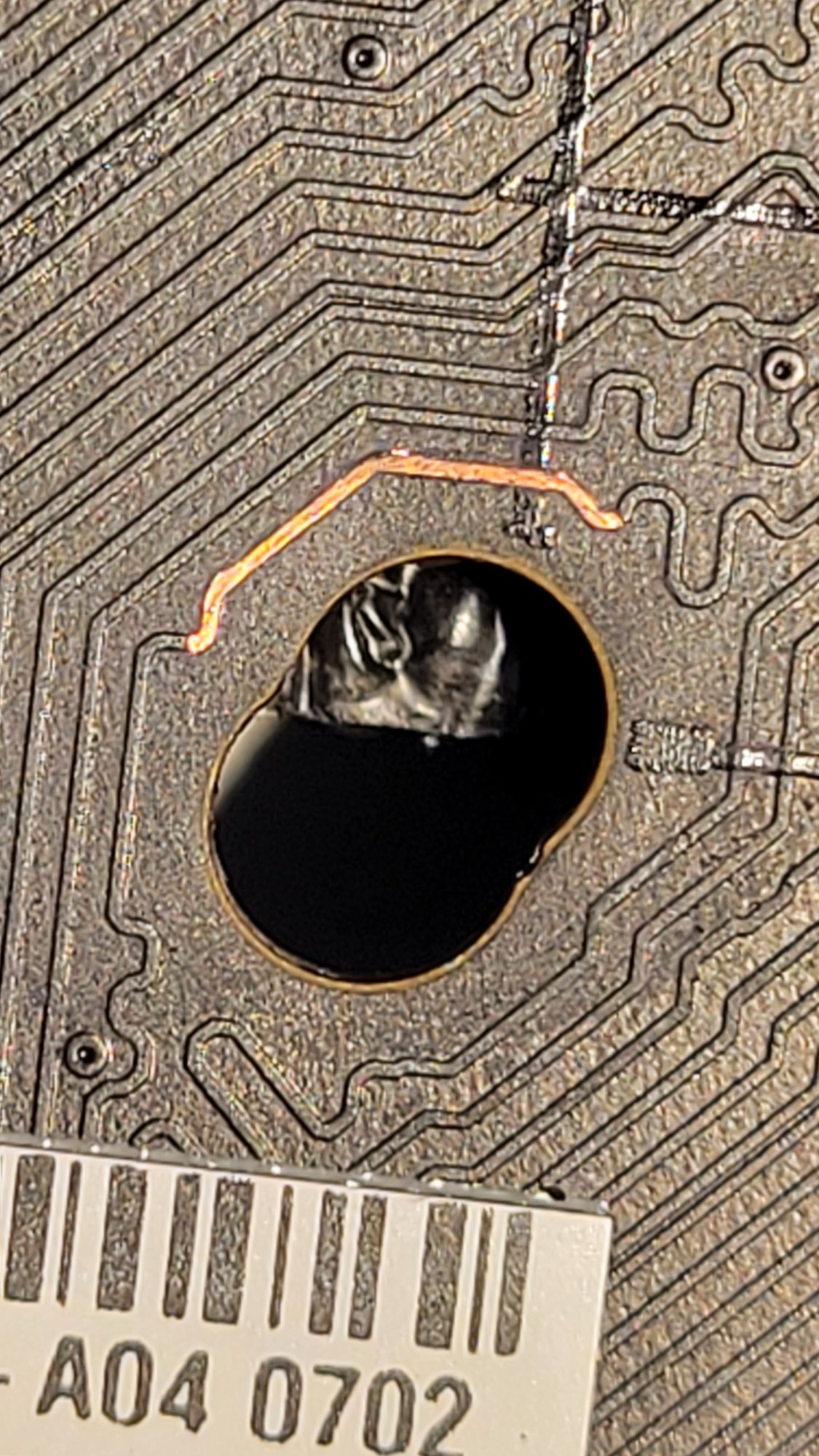

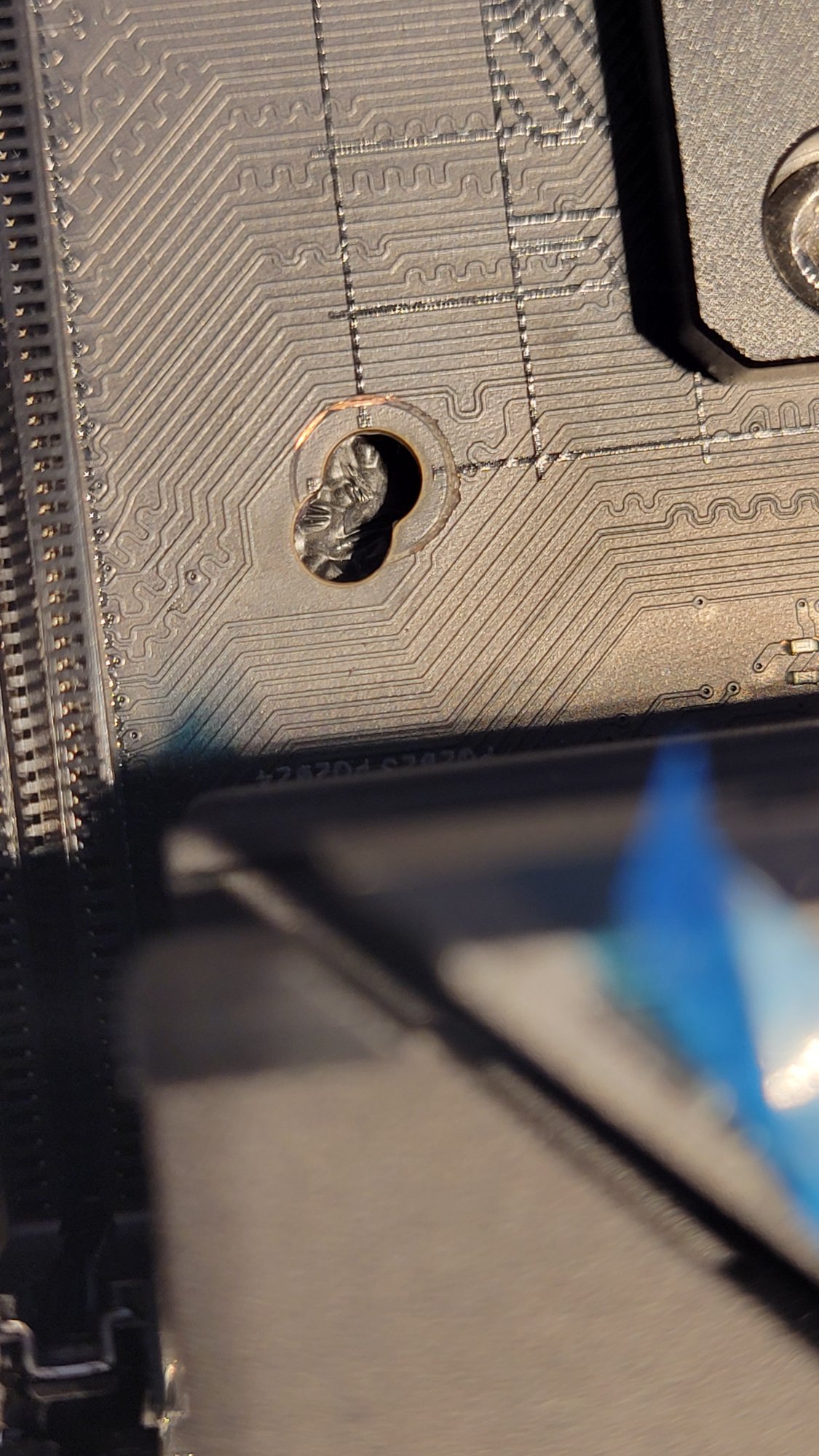

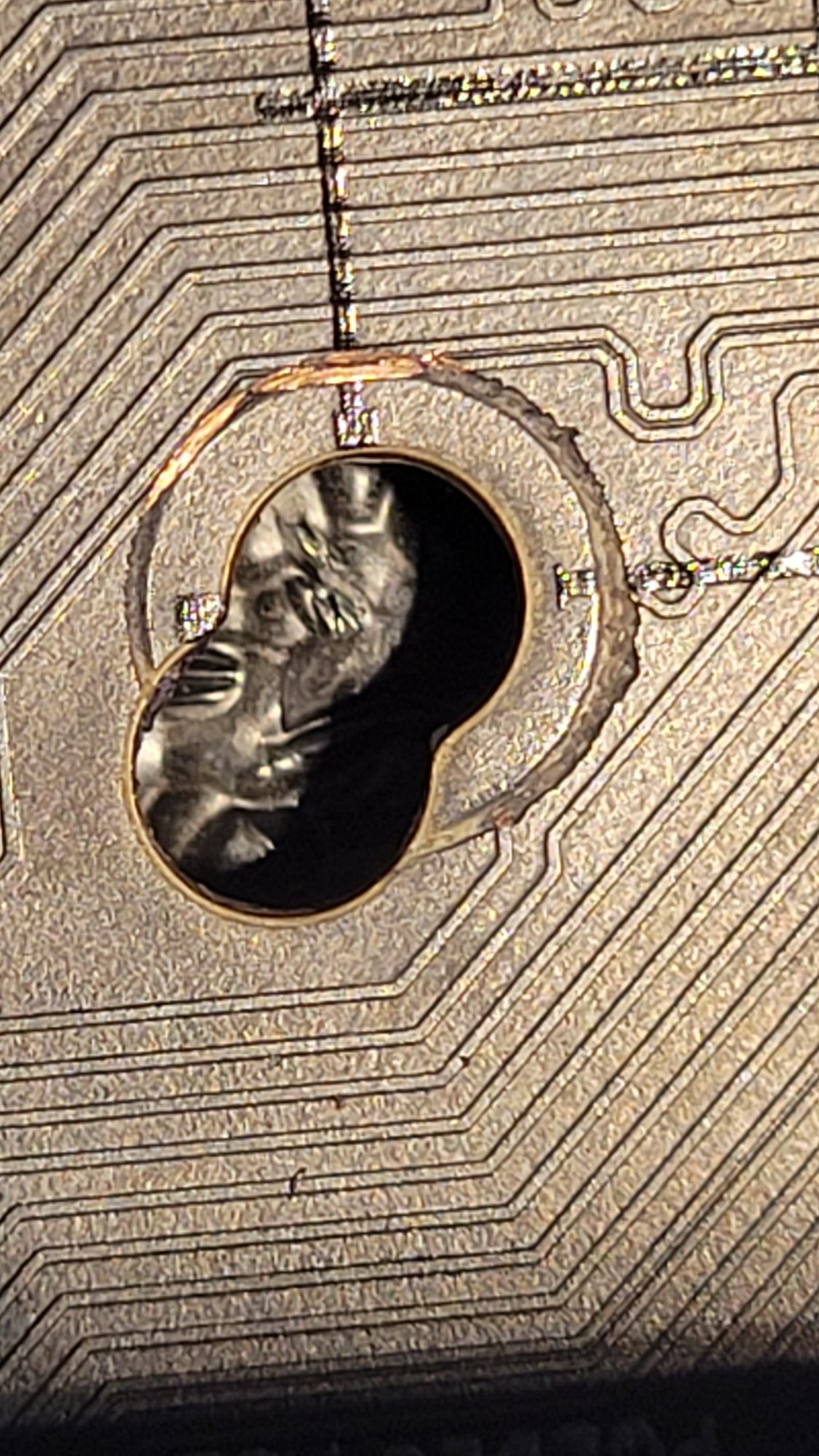

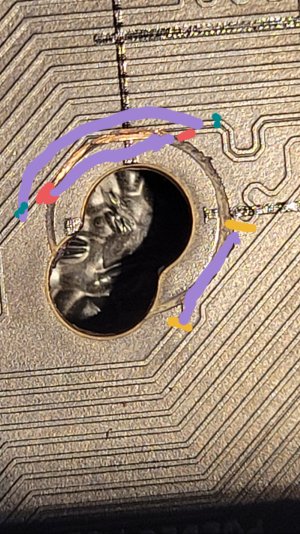

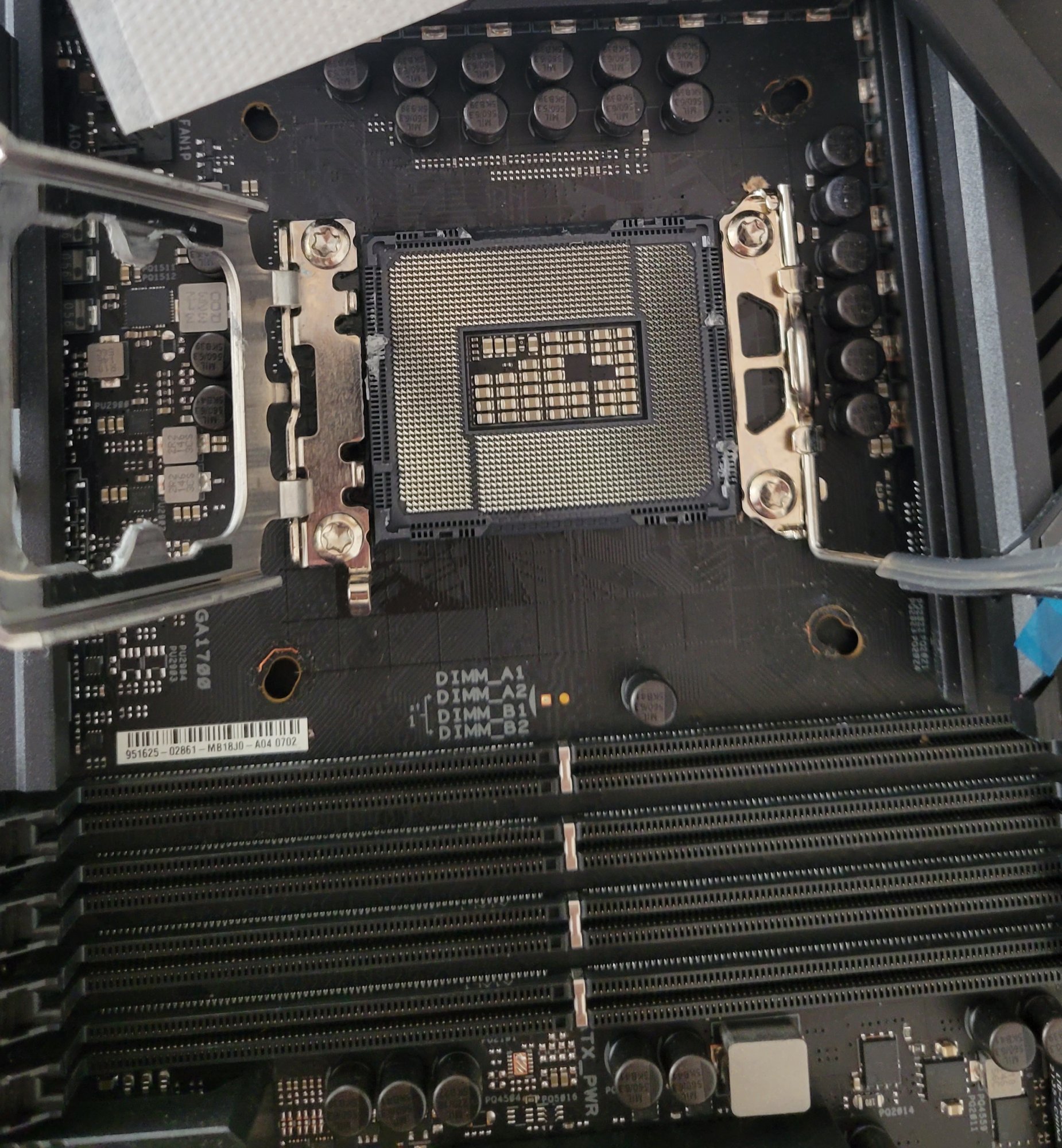

I have a motherboard with some damage around the mounting points for the cpu cooler. Looks to have dug into the PCB and caused damage to the traces. Will only post with ram in B1 or B2 Dimm slots.

Is this repairable? Should I bother, or would it be a waste of my time looking for someone to fix it?

Is this repairable? Should I bother, or would it be a waste of my time looking for someone to fix it?

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)