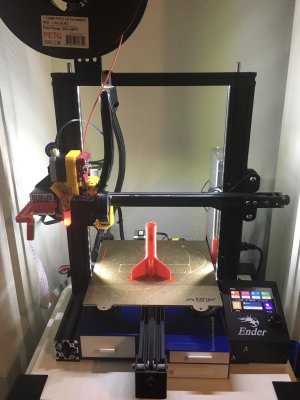

Got my Ender 3 perfected, I think.

This is the direct drive printed kit I settled on, after trying 2 other ones that I didn't care for.

https://www.thingiverse.com/thing:4002782

I used the new SKR Mini E3 v2.0 which has two separate Z stepper motor ports. I tried a belt driven dual Z from Aliexpress which ended up being garbage, and finally settled on a dual Z motor kit from Amazon for around $40.

Printed this Benchy with a 0.6mm nozzle using Inland PETG at 230c/80c, 60mm/s, retractions 1.5mm at 30mm/s. Damn near perfect result for the first run on the new setup.

Now on to making functional parts that won't warp in the heat!

This is the direct drive printed kit I settled on, after trying 2 other ones that I didn't care for.

https://www.thingiverse.com/thing:4002782

I used the new SKR Mini E3 v2.0 which has two separate Z stepper motor ports. I tried a belt driven dual Z from Aliexpress which ended up being garbage, and finally settled on a dual Z motor kit from Amazon for around $40.

Printed this Benchy with a 0.6mm nozzle using Inland PETG at 230c/80c, 60mm/s, retractions 1.5mm at 30mm/s. Damn near perfect result for the first run on the new setup.

Now on to making functional parts that won't warp in the heat!

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)