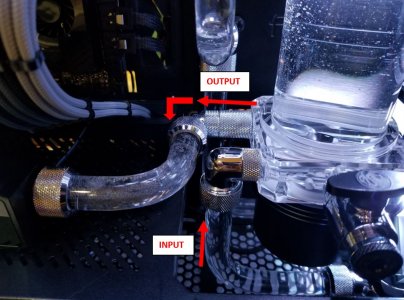

Hi everyone, I just got a Singularity Computers Protium D5 reservoir and an alphacool VP655 D5 PWM pump. I?m testing them out of my system to make sure that the pump works fine before installing it in my build. Water travels from the radiator up to the inlet of the pump/reservoir and then it leaves the pump into the green tube (testing only) going back into the radiator. My question is this, there is a huge air bubble in the green tube close to the outlet of the pump and it looks like the pump isn?t able to pump the water strong enough causing the massive air bubble. It looks like water is just trickling down the green tube. Is this normal? I made a video and posted it in the link below.

At first, I thought this might be caused by the 90 degree inlet bend restricting the water flow into the pump. But then again, the pump is gravity fed by the reservoir so there is plenty of water feeding the pump and this shouldn?t be a feeding/intake problem.

I tried using a different D5 pump (Laing D5T Vario) and I get the same result. I also tried a different PSU (EVGA 850W) and get the same result.

So is that massive air bubble normal when water is leaving the pump? Or do I have to wait for it to naturally bleed itself out of the loop? I?m worried that my pump isn?t strong enough, but then again, I know D5 pumps can push through a lot. Any comments/suggestions would be helpful, thanks.

At first, I thought this might be caused by the 90 degree inlet bend restricting the water flow into the pump. But then again, the pump is gravity fed by the reservoir so there is plenty of water feeding the pump and this shouldn?t be a feeding/intake problem.

I tried using a different D5 pump (Laing D5T Vario) and I get the same result. I also tried a different PSU (EVGA 850W) and get the same result.

So is that massive air bubble normal when water is leaving the pump? Or do I have to wait for it to naturally bleed itself out of the loop? I?m worried that my pump isn?t strong enough, but then again, I know D5 pumps can push through a lot. Any comments/suggestions would be helpful, thanks.

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)