Rev. Night

[H]ard|Gawd

- Joined

- Mar 30, 2004

- Messages

- 1,489

Hi all,

I am about to tackle a few liquid metal projects (1 cpu, 2 gpu) using TG Conductonaut and I thought I had all my bases covered. Now I am reading that TG only recommends using it on nickle-based copper IHS/heatsinks. All 3 of the intended items are 100% copper, not nickle based. Does this mean that I can't use liquid metal on 100% copper? Will it need to be replaced in a year? I have zero interest delidding this yearly. A few reddit threads are saying that GA + CU = CU Alloy, can lead to issues.

FYI, I will be using Kapton tape around all dies/heatsinks to help protect the pcb. Delid will be sealed in the 4 corners by crazy glue.

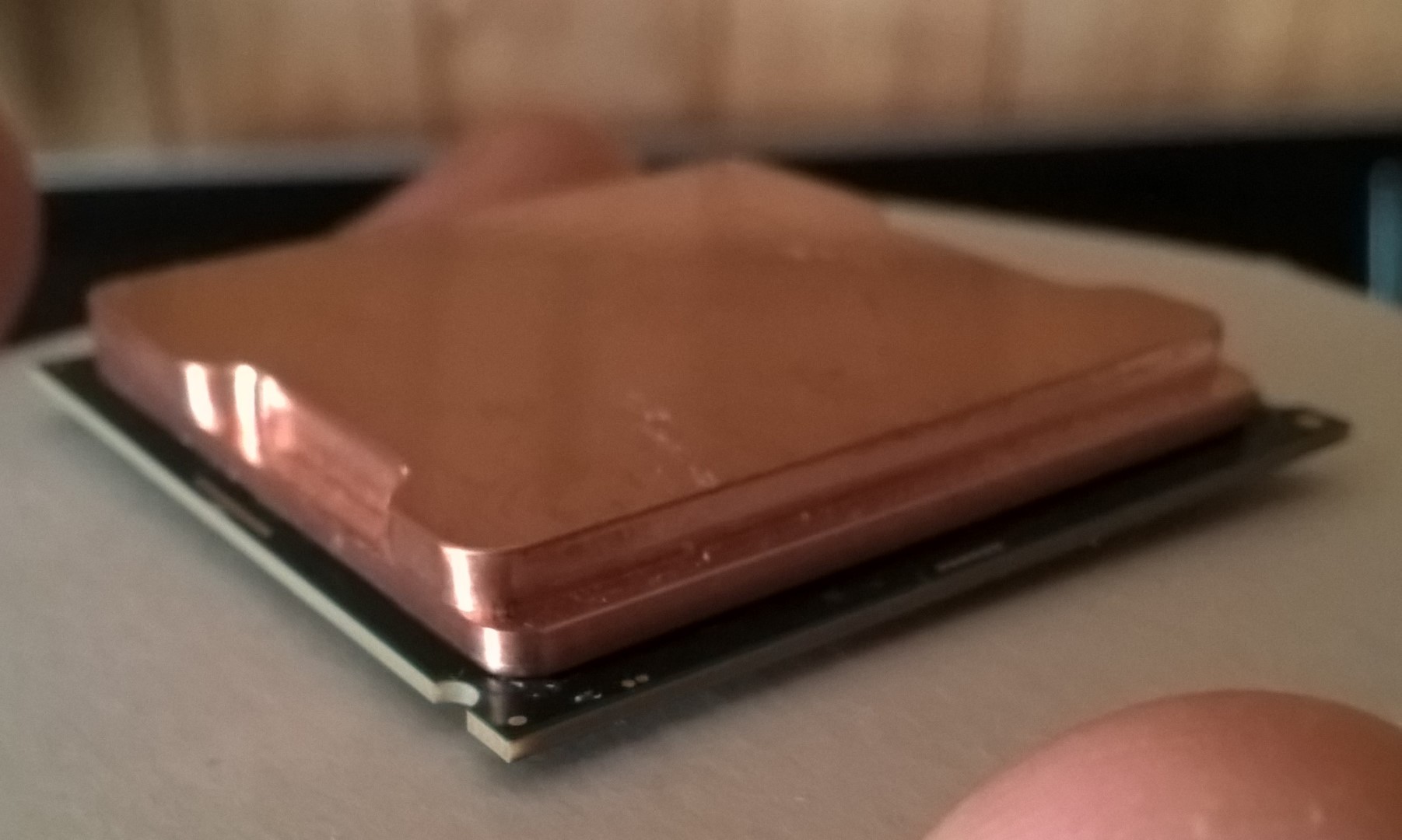

CPU: I7-6700K Delid. Copper IHS from Rockit 88

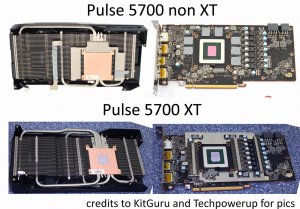

GPU 1: Sapphire Pulse 5700xt

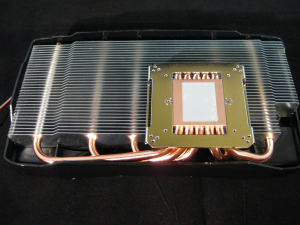

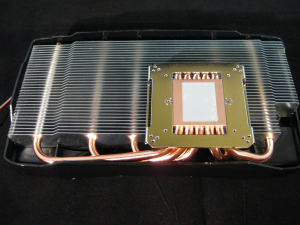

GPU 2: Sapphire Nitro 480x with Arctic Cooler Twin Turbo II

I am about to tackle a few liquid metal projects (1 cpu, 2 gpu) using TG Conductonaut and I thought I had all my bases covered. Now I am reading that TG only recommends using it on nickle-based copper IHS/heatsinks. All 3 of the intended items are 100% copper, not nickle based. Does this mean that I can't use liquid metal on 100% copper? Will it need to be replaced in a year? I have zero interest delidding this yearly. A few reddit threads are saying that GA + CU = CU Alloy, can lead to issues.

FYI, I will be using Kapton tape around all dies/heatsinks to help protect the pcb. Delid will be sealed in the 4 corners by crazy glue.

CPU: I7-6700K Delid. Copper IHS from Rockit 88

GPU 1: Sapphire Pulse 5700xt

GPU 2: Sapphire Nitro 480x with Arctic Cooler Twin Turbo II

![[H]ard|Forum](/styles/hardforum/xenforo/logo_dark.png)