Catsonar

[H]ard|Gawd

- Joined

- Oct 3, 2003

- Messages

- 1,886

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hello,

Does anyone have experience with these flow sensors? How do you like them? Where did you get yours from?

They have been extremely difficult to find.I have one works and it works very well. Seems accurate enough for flow as well as temperature monitoring, at least when compared to the other 3 fluid temperature sensors in my system.

Mine has never clicked or had any if the issues the prior gen ones had. Based on what aquacomputer says the internals are new or at least updated.

There is a flow sensor only verion, the High Flow 2, that does not have any of the additional features, no led screen, no rgb, no temperature monitoring etc.

The bonus of the Next is that it gives you access to aquasuite, a fluid temp sensor, external temp sensor, and aquacomputers RGBpx. The screen is configurable with several data points. The rgb ring can be set as a visual flow meter, or through the extremely configurable Aquasuite RGBpx.

I bought mine directly from Aquacomputer, but I am in Germany so it only takes a couple of days, and there is no import junk to deal with. However they have been hit and miss for being instock the last year or so.

I have one works and it works very well. Seems accurate enough for flow as well as temperature monitoring, at least when compared to the other 3 fluid temperature sensors in my system.

Mine has never clicked or had any if the issues the prior gen ones had. Based on what aquacomputer says the internals are new or at least updated.

There is a flow sensor only verion, the High Flow 2, that does not have any of the additional features, no led screen, no rgb, no temperature monitoring etc.

The bonus of the Next is that it gives you access to aquasuite, a fluid temp sensor, external temp sensor, and aquacomputers RGBpx. The screen is configurable with several data points. The rgb ring can be set as a visual flow meter, or through the extremely configurable Aquasuite RGBpx.

I bought mine directly from Aquacomputer, but I am in Germany so it only takes a couple of days, and there is no import junk to deal with. However they have been hit and miss for being instock the last year or so.

Interesting. I did not know this. How do the new ones hook up to your system?

The old ones had a proprietary 3 pin flow sensor connector that hookes straight up to an Aquaero 5 or 6, requiring an Aquaero in order to work, but it sounds like with all these new features (and the lack of mention of the Aquaero) something may have changed here.

I'm about to put one of the aquacool mps 400 flow sensors into my loop. It has its own USB connection as well as an aquabus connection. I bought it from performance pcs which is where I buy pretty much everything. I'll bet that the internals of it and the next are pretty similar. Just rub or internal water temp sensor. It does have a port to attach an external temp sensor and alarm/rpm cable.

https://www.performance-pcs.com/wat...w-rate-sensor-mps-flow-400-g1-4-aq-53132.html

Damn, all the way to 400 L/H? I've red that anything above 220 L/H is pointless and doesn't aid to cooling. Ideal is the range of 65-220 L/H.You have to watch out with the MPS ones as they have narrower ranges for flow than the other sensors, but the MPS 400 is the one I would go with. It covers the range of 80-400 LPH, which is ~0.35 to 1.75 GPM, which ought to cover the ranges of a good loop.

I'd avoid the MPS 100 or MPS 200 models though, as they are for much lower flow. I don't even know why they make them, but apparently the Germans seem to think that our ~1GPM rule of thumb is extreme overkill. They must not have been looking at the data showing strong temperature improvements up to 1 GPM, and it starting to taper off above 1GPM, but continuing to improve (with diminishing returns) up to about 1.5GPM on most blocks and radiators.

Damn, all the way to 400 L/H? I've red that anything above 220 L/H is pointless and doesn't aid to cooling. Ideal is the range of 65-220 L/H.

I'm going to have to disagree with that range.

IF you use PWM to control pump speed 65LPH (~0.29 GPM) isn't a bad minimum flow rate to use at idle when load is low, but if that is your flow rate at full load on a hot system, you are going to get higher temps than your system is capable of achieving.

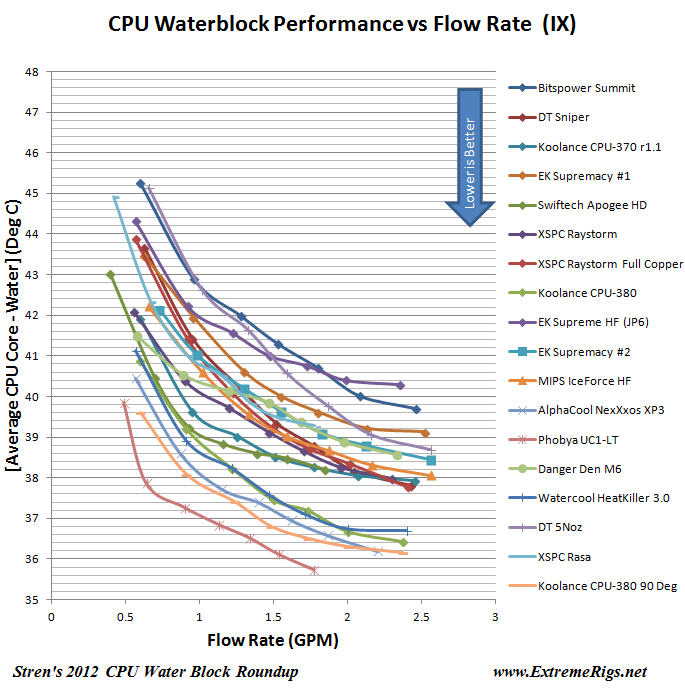

The good old rule of thumb is to target hitting at least 1 GPM at load. This is about 230LPH. You will continue to see some temperature improvements as that flow rate rises above 1GPM, but at a much lower rate.

The ideal flow rate for a water cooling loop is where the coolant passes so quickly through blocks and radiators that there isn't a significant difference in temperature in different locations in the loop. In other words, coolant temp after the block is not hotter than it is before the block, and coolant temp after the radiator is not cooler than before the radiator. You have then reached a steady state.

Now, there is of course always going to be a slightly higher temp after a block, and a slightly lower temp after a radiator, but the goal is to get them to the point where they are not measurably different, this way you maximize the cooling capacity across the water block. If the coolant flows so slowly through the block that it is allowed to noticeably increase in temperature, you will get a reduced rate of heat transfer from the block to the coolant, as heat transfer is in part dependent on the difference in temperature, and the warmer the coolant is allowed to get, the smaller that temperature delta will be in the block.

You mostly get there at 1 GPM, which is why it became the PC Water Cooling rule of thumb years ago. There is going to be some variability depending on water block and radiator design, but in general, if you are hitting 1GPM you are doing pretty well, and if you aren't, you could benefit from increasing flow.

As mentioned before, the Germans (at least Aquacomputer, not sure about Watercool or Alphacool) seem to prefer lower flow rates for some reason, and they give much lower recommendations than we do here. I've never understood why. Any data you find on the subject is pretty clear that a loops performance improves greatly up to 1GPM, and continues to improve (but less so) above 1GPM, and Germans are usually pretty proud when it comes to their engineering, math and evidence based approaches to design. Maybe they think it is "good enough?"

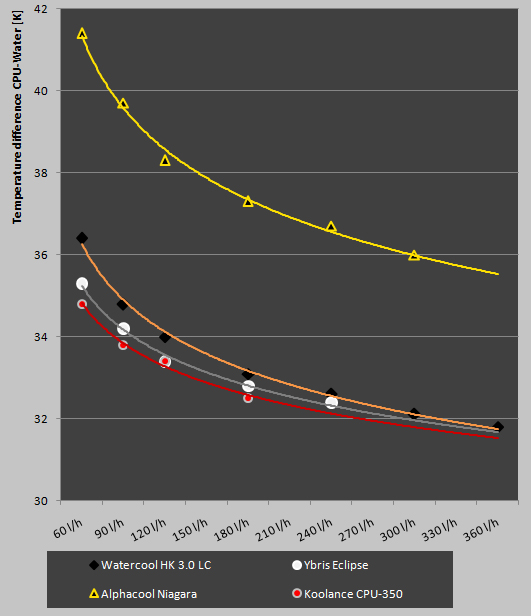

This is a little old (simply because the rise of the Youtube Star menas very few people are doing good written reviews anymore with good testing, so a lot of information just isn't being created anymore. I am not familliar with these blocks. They must have been big in 2009, but I don't know them now, but I guarantee you that the flow rate vs. temperature relationship still looks similar on modern blocks.

View attachment 445891

As you can see, there is continued improvement up until 360LPH, and the shape of the curve suggests that it continues to improve beyond that. Some might say that the difference is small an insignificant, but I would disagree. In PC cooling even a single degree can make a huge difference. It can be the difference between a stable overclock or a crash, or the difference between loud fans at full blast, and relative silence.

Aslo worth nothing that the more heat you output the bigger the benefit from higher flow will be. This testing was done on an i7-920, a 130W TDP CPU. Depending on your system, its TDP and how much you overclock it, your benefit will be be either greater or less than depicted here. I find that on modern CPU's (except beasts like an overclocked Threadripper) this is a bit moot these days, but the bigger benefit comes from the GPU, especially if you have a high end beast with an overridden power limit (like my 430W 6900xt) I just can't find GPU based data on this. Maybe I'll do some measurements myself and post back here later.

Either way, talk to anyone who has been water cooling for years, and they will likely tell you, the best you can do is measure on your own system and see what results you get, but as a rule of thumb 1GPM isn't bad. It is achievable in most loops with common pumps on the market, and it provides good performance, making the most out of your blocks. As with everything else it is going to be highly system dependent. IN some cases, adding more pump capacity can actually dump more heat into the loop from the pump than it improves from higher flow rates, which can have the opposite effect as well.

Awesome reply, thank you. So yes, 65 L/H was meant to be with PWM pumps and at idle for components. So I might have been off by ten but from what I had read long time ago I agree with the 1GPM rule. Ok, so it was 230 L/H but that cooling still occurs even after that point just to a slower extent.I'm going to have to disagree with that range.

IF you use PWM to control pump speed 65LPH (~0.29 GPM) isn't a bad minimum flow rate to use at idle when load is low, but if that is your flow rate at full load on a hot system, you are going to get higher temps than your system is capable of achieving.

The good old rule of thumb is to target hitting at least 1 GPM at load. This is about 230LPH. You will continue to see some temperature improvements as that flow rate rises above 1GPM, but at a much lower rate.

The ideal flow rate for a water cooling loop is where the coolant passes so quickly through blocks and radiators that there isn't a significant difference in temperature in different locations in the loop. In other words, coolant temp after the block is not hotter than it is before the block, and coolant temp after the radiator is not cooler than before the radiator. You have then reached a steady state.

Now, there is of course always going to be a slightly higher temp after a block, and a slightly lower temp after a radiator, but the goal is to get them to the point where they are not measurably different, this way you maximize the cooling capacity across the water block. If the coolant flows so slowly through the block that it is allowed to noticeably increase in temperature, you will get a reduced rate of heat transfer from the block to the coolant, as heat transfer is in part dependent on the difference in temperature, and the warmer the coolant is allowed to get, the smaller that temperature delta will be in the block.

You mostly get there at 1 GPM, which is why it became the PC Water Cooling rule of thumb years ago. There is going to be some variability depending on water block and radiator design, but in general, if you are hitting 1GPM you are doing pretty well, and if you aren't, you could benefit from increasing flow.

As mentioned before, the Germans (at least Aquacomputer, not sure about Watercool or Alphacool) seem to prefer lower flow rates for some reason, and they give much lower recommendations than we do here. I've never understood why. Any data you find on the subject is pretty clear that a loops performance improves greatly up to 1GPM, and continues to improve (but less so) above 1GPM, and Germans are usually pretty proud when it comes to their engineering, math and evidence based approaches to design. Maybe they think it is "good enough?"

This is a little old (simply because the rise of the Youtube Star menas very few people are doing good written reviews anymore with good testing, so a lot of information just isn't being created anymore. I am not familliar with these blocks. They must have been big in 2009, but I don't know them now, but I guarantee you that the flow rate vs. temperature relationship still looks similar on modern blocks.

View attachment 445891

As you can see, there is continued improvement up until 360LPH, and the shape of the curve suggests that it continues to improve beyond that. Some might say that the difference is small an insignificant, but I would disagree. In PC cooling even a single degree can make a huge difference. It can be the difference between a stable overclock or a crash, or the difference between loud fans at full blast, and relative silence.

Aslo worth nothing that the more heat you output the bigger the benefit from higher flow will be. This testing was done on an i7-920, a 130W TDP CPU. Depending on your system, its TDP and how much you overclock it, your benefit will be be either greater or less than depicted here. I find that on modern CPU's (except beasts like an overclocked Threadripper) this is a bit moot these days, but the bigger benefit comes from the GPU, especially if you have a high end beast with an overridden power limit (like my 430W 6900xt) I just can't find GPU based data on this. Maybe I'll do some measurements myself and post back here later.

Either way, talk to anyone who has been water cooling for years, and they will likely tell you, the best you can do is measure on your own system and see what results you get, but as a rule of thumb 1GPM isn't bad. It is achievable in most loops with common pumps on the market, and it provides good performance, making the most out of your blocks. As with everything else it is going to be highly system dependent. IN some cases, adding more pump capacity can actually dump more heat into the loop from the pump than it improves from higher flow rates, which can have the opposite effect as well.

Awesome reply, thank you. So yes, 65 L/H was meant to be with PWM pumps and at idle for components. So I might have been off by ten but from what I had read long time ago I agree with the 1GPM rule. Ok, so it was 230 L/H but that cooling still occurs even after that point just to a slower extent.

Thank you also on the pump insight. In my new build I have x4 560mm rads w/push&pull and a total of 6 D5 pumps total. 3 for for each loop, 2 loops total splitting rads in half. Hope 3 doesn't adversely effect things though hopefully with that much surface area it won't be a big deal.

It's two loops with two systems in one case. Each loop will cool a GPU/CPU.Wow, that's pretty massive. I've never seen a build with that many pumps. Are you running dedicated loops for GPU/CPU or what is your setup?

I always caution against running multiple loops. It can look pretty with different colors in each, but you are almost always better served by combining everything together.

The reason for this is simple. If your GPU is at max load, and your CPU isn't, the dedicated loop on your GPU is going to be working much harder than the dedicated loop on your CPU, and some of the radiator capacity on your CPU loop is going to be wasted.

By combining them, you are always going to best take advantage of all your radiators, and thus get lower average temps. In a worst case scenario, where all of your dedicated loops are perfectly balanced (this never happens) the worst you can expect from moving to a combined loop with all components at max load, is the same temp as you'd see in the separate loops.

Of course, when you start getting really huge like you have you wind up with the problem that a single loop with a huge number of radiators and blocks, you are going to have a tough time achieving the flow rates you want. You can start doubling up pumps in series, but that only buys you a small improvement in flow rates, at a doubling of pump-sourced heat penalties.

Reducing restriction in a loop always seems to have a larger flow rate improvement than adding another pump. (Insert analogies to race cars, removing weight vs. adding more engine power. Removing the weight almost always has more of a benefit)

I spent some time thinking about how to tackle this on my build and decided, why not run multiple loops using the same coolant, mixed in the reservoir?

This way I could break up the loop into less restrictive parts, where only one pump was necessary to achieve the desired flow rates, yet still maximize the radiator capacity as if everything were in one large loop.

I'm currently in an interim state.

Right now, I have one dedicated loop with one pump that does nothing but push fluid through my CPU and GPU blocks and then dumps it back in the reservoir.

Then I have a second loop (currently with two pumps) that does nothing but pump fluid through my radiators (2x 480mm, and 1x 420mm).

My future state (if I ever get around to start building it, I already have all the parts, but just haven't had time since I bought a house, and moved and did other things) is to split things even further.

The one "hot" loop for the CPU and GPU is going to stay the same, but the "cold" radiator loop is going to split in two, with each of those loops having a 480mm and a 360mm radiator, one pump each, and all three loops combining and mixing in the reservoir.

This way I should get maximum flow, with minimum pumping, and and all together more efficient system.

That is, unless I get to my next gen build first.

I've toyed with the idea of just getting rid of my massive and inconvenient Corsair 1000D case, and just doing an external cooling loop.

I've always wanted to achieve the best mix of silence and power, and I figure that now that I own my own home and won't be forced to move for a while, I can run a couple of LONG tubes to another room, and stick a water chiller in that room. One of these should do the trick when they come back in stock, provided 790w is sufficient capacity.

I figured I could use that insulating foam from the hardware store, they use around copper tubing, to keep the fluid cool, and run it slightly sub-ambient (but above the dew point, so I don't get condensation)

This way the pumps and the chiller would be out of earshot. The only thing making noise in my office would be the case fans, and those would be super quiet low speed fans.

There are some design challenges though. With a chiller, in order to avoid having it constantly turn on and off, and kill the compressor, I figure I'd need a large reservoir with lots of coolant, to stabilize temperatures somewhat.

I'm thinking I'd use a 5 gallon glass carboy typically used for home brewing as a reservoir, with an insulated jacket around it to keep it cool. I'd need to drill holes in the bottom of it with a diamond hole saw, and fit some form of barb fittings for tubing.. I'd install two loops. One with a single pump, that pushes fluid through the chiller and right back into the carboy to keep the coolant cool. The second loop would use two pumps in series (just to help overcome the resistance of the long tubing run (probably 30 ft? 9M?) to just go to the case and back to cool the two blocks.

I'd have to do some custom wiring though, as I'd need to send a PWM signal to the pump from the Aquaero in the computer, so it can speed up the pump speed with temperatures. I'd also need a long 12v line to trigger a relay for a power supply that powers on the remote pumps near the chiller when the PC turns on.

I'm thinking I could probably just use a Cat7 cable, using both wires in one of the twisted pairs to carry the PWM signal, and the remaining wires to carry the 12V and ground needed to trigger the relay. (hopefully this won't draw too much current, or I'd need bigger wires than cat7 offers)

This is still a ways off. A fun project I have given some thought to, but I have many other projects to finish first. I just don't know if I want to spend the time and effort on further splitting up my current loops, if that isn't going to be a long term solution

It's two loops with two systems in one case. Each loop will cool a GPU/CPU.

Late reply, but I'm running these in three machines. For a test, I connected all three in series to see how they compared to each other. Temps were within 1C and flow rate @ 140l/h was within 2%, so I'd say they are very consistent. The OLED display and RGB ring (both fully programmable & capable of being turned off) are nice, and the integration into the Aquacomputer eco system is also good. The coolant quality sensor is kind of neat. One of them helped alert me to a block that had a plating issue before I ever would have known. I run these as sensors within Aquaero-controlled cooling systems.Hello,

Does anyone have experience with these flow sensors? How do you like them? Where did you get yours from?

Late reply, but I'm running these in three machines. For a test, I connected all three in series to see how they compared to each other. Temps were within 1C and flow rate @ 140l/h was within 2%, so I'd say they are very consistent. The OLED display and RGB ring (both fully programmable & capable of being turned off) are nice, and the integration into the Aquacomputer eco system is also good. The coolant quality sensor is kind of neat. One of them helped alert me to a block that had a plating issue before I ever would have known. I run these as sensors within Aquaero-controlled cooling systems.

I'm going to be using one or two of these in my forthcoming rack cooler as well.

From the website:Interesting. How do they determine coolant quality? Is it just a measure of conductivity?

Sensor for coolant quality

A very precise measuring system for the electrical conductivity of the coolant is integrated into the high flow NEXT. It is capable to measure the conductivity between 2-200 µS and determine the quality of the coolant. If corrosion occurs or if the corrosion protection inhibitors are used up, the conductivity of the coolant increases significantly. In this case, the coolant should be replaced.

From the website:

It said sold out and shipping in 6 weeks or something like that when I ordered from aquacomputer.de, but both sensors shipped the next day.So, turns out i got two flow sensors from Aquacomputer's German/UK website. They are sold out in most places except for their home website. Even with shipping it was still cheaper than the two idiots on Ebay selling them for $295 each. I paid a total of $203( two Flow sensors and shipping). They also told me that all their vendors have sold out and that they will be the only ones selling flow sensor at this time.

They probably recommend 0.5gpm because a lot of waterblocks have low difference between 0.5gpm and 1gpm while they noise level from a d5 gets quite audible above 60%. If you are watercooling for low noise and good temps then running a noisy pump kind of ruins the point. My CPU loop shows around 0.7 degrees difference between aprox. 0.5 and 1.1gpm (50% vs 100% pump speed) but it is much louder with pumps at 100%. The difference is aprox. 1.5dbA and the noise is also much higher pitched than fan noise. For everyday use I would much rather run my pump at 50-60% and give up a few degrees performance than have the extra noise. I do run my system at sub 30dbA at idle and it tops out at around 31dbA at full load in steady state, when measured about 5cm from the air inntake.Wow, that's pretty massive. I've never seen a build with that many pumps. Are you running dedicated loops for GPU/CPU or what is your setup?

I always caution against running multiple loops. It can look pretty with different colors in each, but you are almost always better served by combining everything together.

The reason for this is simple. If your GPU is at max load, and your CPU isn't, the dedicated loop on your GPU is going to be working much harder than the dedicated loop on your CPU, and some of the radiator capacity on your CPU loop is going to be wasted.

By combining them, you are always going to best take advantage of all your radiators, and thus get lower average temps. In a worst case scenario, where all of your dedicated loops are perfectly balanced (this never happens) the worst you can expect from moving to a combined loop with all components at max load, is the same temp as you'd see in the separate loops.

Of course, when you start getting really huge like you have you wind up with the problem that a single loop with a huge number of radiators and blocks, you are going to have a tough time achieving the flow rates you want. You can start doubling up pumps in series, but that only buys you a small improvement in flow rates, at a doubling of pump-sourced heat penalties.

Reducing restriction in a loop always seems to have a larger flow rate improvement than adding another pump. (Insert analogies to race cars, removing weight vs. adding more engine power. Removing the weight almost always has more of a benefit)

I spent some time thinking about how to tackle this on my build and decided, why not run multiple loops using the same coolant, mixed in the reservoir?

This way I could break up the loop into less restrictive parts, where only one pump was necessary to achieve the desired flow rates, yet still maximize the radiator capacity as if everything were in one large loop.

I'm currently in an interim state.

Right now, I have one dedicated loop with one pump that does nothing but push fluid through my CPU and GPU blocks and then dumps it back in the reservoir.

Then I have a second loop (currently with two pumps) that does nothing but pump fluid through my radiators (2x 480mm, and 1x 420mm).

My future state (if I ever get around to start building it, I already have all the parts, but just haven't had time since I bought a house, and moved and did other things) is to split things even further.

The one "hot" loop for the CPU and GPU is going to stay the same, but the "cold" radiator loop is going to split in two, with each of those loops having a 480mm and a 360mm radiator, one pump each, and all three loops combining and mixing in the reservoir.

This way I should get maximum flow, with minimum pumping, and and all together more efficient system.

That is, unless I get to my next gen build first.

I've toyed with the idea of just getting rid of my massive and inconvenient Corsair 1000D case, and just doing an external cooling loop.

I've always wanted to achieve the best mix of silence and power, and I figure that now that I own my own home and won't be forced to move for a while, I can run a couple of LONG tubes to another room, and stick a water chiller in that room. One of these should do the trick when they come back in stock, provided 790w is sufficient capacity.

I figured I could use that insulating foam from the hardware store, they use around copper tubing, to keep the fluid cool, and run it slightly sub-ambient (but above the dew point, so I don't get condensation)

This way the pumps and the chiller would be out of earshot. The only thing making noise in my office would be the case fans, and those would be super quiet low speed fans.

There are some design challenges though. With a chiller, in order to avoid having it constantly turn on and off, and kill the compressor, I figure I'd need a large reservoir with lots of coolant, to stabilize temperatures somewhat.

I'm thinking I'd use a 5 gallon glass carboy typically used for home brewing as a reservoir, with an insulated jacket around it to keep it cool. I'd need to drill holes in the bottom of it with a diamond hole saw, and fit some form of barb fittings for tubing.. I'd install two loops. One with a single pump, that pushes fluid through the chiller and right back into the carboy to keep the coolant cool. The second loop would use two pumps in series (just to help overcome the resistance of the long tubing run (probably 30 ft? 9M?) to just go to the case and back to cool the two blocks.

I'd have to do some custom wiring though, as I'd need to send a PWM signal to the pump from the Aquaero in the computer, so it can speed up the pump speed with temperatures. I'd also need a long 12v line to trigger a relay for a power supply that powers on the remote pumps near the chiller when the PC turns on.

I'm thinking I could probably just use a Cat7 cable, using both wires in one of the twisted pairs to carry the PWM signal, and the remaining wires to carry the 12V and ground needed to trigger the relay. (hopefully this won't draw too much current, or I'd need bigger wires than cat7 offers)

This is still a ways off. A fun project I have given some thought to, but I have many other projects to finish first. I just don't know if I want to spend the time and effort on further splitting up my current loops, if that isn't going to be a long term solution

They probably recommend 0.5gpm because a lot of waterblocks have low difference between 0.5gpm and 1gpm while they noise level from a d5 gets quite audible above 60%. If you are watercooling for low noise and good temps then running a noisy pump kind of ruins the point. My CPU loop shows around 0.7 degrees difference between aprox. 0.5 and 1.1gpm (50% vs 100% pump speed) but it is much louder with pumps at 100%. The difference is aprox. 1.5dbA and the noise is also much higher pitched than fan noise. For everyday use I would much rather run my pump at 50-60% and give up a few degrees performance than have the extra noise. I do run my system at sub 30dbA at idle and it tops out at around 31dbA at full load in steady state, when measured about 5cm from the air inntake.

Well my idle noise with pumps at 100 is higher than my stable state noise level. I have enough capacity that I don't need to ramp up the fans much and difference in temp between 40dbA and 31dbA is only a few degrees. Some water blocks have very large differences between flow rates while others have very low differences, it depends a lot on the cooling engine.At full CPU/GPU load that is much less of a difference than in my current system, or in any system I've ever built. Generally the difference between 0.5gpm and the 1.1 to 1.3gpm I get at full load is well over a degree, if not more.

I agree that the pumps make more noise at full speed, but even at their max noise levels they are quieter than fully ramped up fans, and if you have a target core temperature you are trying to meet, any loss in temperature resultant from pump speed has to be made up for by higher fan speeds, and the fans usually wind up drowning out even the loudest pumps when they have to wind up.

Also, that's what PWM poump control is for. Only use the higher pump speeds when needed. At idle mine sits at only 40%. I do have it move up to 100% at high load though.

Well my idle noise with pumps at 100 is higher than my stable state noise level. I have enough capacity that I don't need to ramp up the fans much and difference in temp between 40dbA and 31dbA is only a few degrees. Some water blocks have very large differences between flow rates while others have very low differences, it depends a lot on the cooling engine.

Yeah, you probably have 180-200watts more to cool and less radiator surface. I do dual loop so the CPU is not affected by the GPU and also due to the fat 2x360s at the top are drawing air from the case so they would only add maybe 10-15% more capacity if CPU and GPU was on the same loop. The fat 2x480 up front for the CPU setup heats the incoming air close to water temp, but thankfully the water temp is not very high for the CPU loop so case air temps doesn't suffer all that much. My CPU block is also supposed to be the least sensitive to flow rate of the AM4 blocks and a few degrees better than the EK Velocity that I used before.Yeah, I have lots of capacity too (two 480's and one 420, all three in push/pull) but I'm also cooling a Threadripper 3960x and a specialty 6900xt which dra s 430w, so I have a lot of heat to get rid of

Yeah, I have lots of capacity too (two 480's and one 420, all three in push/pull) but I'm also cooling a Threadripper 3960x and a specialty 6900xt which draws 430w, so I have a lot of heat to get rid of

Why do yall have such tiny rads? 480s and 360s?Yeah, you probably have 180-200watts more to cool and less radiator surface. I do dual loop so the CPU is not affected by the GPU and also due to the fat 2x360s at the top are drawing air from the case so they would only add maybe 10-15% more capacity if CPU and GPU was on the same loop. The fat 2x480 up front for the CPU setup heats the incoming air close to water temp, but thankfully the water temp is not very high for the CPU loop so case air temps doesn't suffer all that much. My CPU block is also supposed to be the least sensitive to flow rate of the AM4 blocks and a few degrees better than the EK Velocity that I used before.

Case restrictions? The 900D maxes out at 480mm, hence why I use the best one possible.Why do yall have such tiny rads? 480s and 360s?

I run two 560mm rads, what do you have to say about that.Why do yall have such tiny rads? 480s and 360s?

The main purpose of the additional external connector is to allow a calculation of the thermal power dissipation.